Dainese experiences

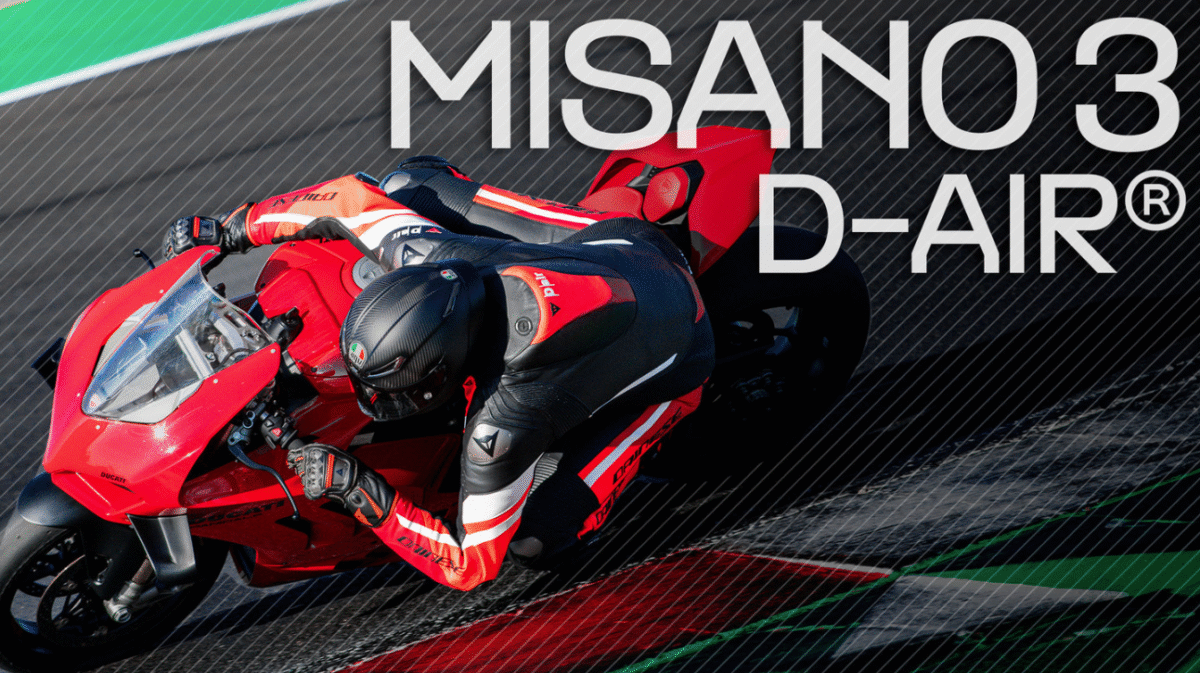

Dainese is a global leader in the development of protective clothing for motorcyclists and racing drivers. With its D-Air® technology, the company has developed an intelligent airbag system for racing suits and streetwear based on sensors, algorithms and electronics.

"I never thought I’d see a colleague take the test system home with them – that’s truly groundbreaking! It even fits in a backpack." Nicolò Bargellesi – Algorithm and AI engineer for models and solutions for airbags and electronics – Dainese

Experiences

Our problem

We develop intelligent airbag systems for racing suits and streetwear. Our key challenges:

- Reliably validating algorithms so that the airbag deploys at the right moment – even with defective sensors or low battery power.

- Preventing false deployments (misfires) while ensuring that the system functions correctly in all relevant scenarios.

- Use a large amount of data from MotoGP races and everyday situations without having to carry out time-consuming manual tests.

- Safety certification of the end product, which requires comprehensive test coverage.

The solution

With PROTOS’ miniHIL, we were able to:

- Test algorithms continuously and automatically – even during development.

- Simulate all relevant scenarios: crashes, normal operation, malfunctions, low battery conditions.

- Perform regression tests after every software change – quickly, repeatably, without hardware load.

- Import historical data from over 15 years of MotoGP and road use in real time.

- Perform certification-relevant safety checks without endangering physical systems.

Before miniHIL, in-depth testing involved a great deal of manual effort – with miniHIL, it is now quick, repeatable and safe.

"The miniHIL gave us certainty – the product is delivered within 24 hours – no problem! Better than human/manual testing." Marco Maculan – Firmware Engineer

Projekt 1: Smart Air & Electronics of Racing Suits (D-Air® Racing)

Description:

- Further development of Racing Suits, examples: Products

- Redesign and validation of airbag algorithms

- Data collection from MotoGP races since 2007 (several terabytes, reduced to relevant cases)

- Use of real data for miniHIL tests in real time

- Test scenarios: normal driving conditions, crash situations, error scenarios

Technical focus:

- Trigger logic of the airbag (correct timing of activation, even with defective sensors or low battery)

- Simulation of defective systems with miniHIL

- Validation: no misfires, correct activation in all situations

- Tests of states such as ‘armed’, error status, low battery charge

Safety is a key factor for us – testing with miniHIL is essential to ensure certification of the end product.

Project 2: Smart D-Air (older version) / Smart Jacket

Description:

- Validation of airbag activation for road products

- Integration of automotive airbag technology (gas generator)

- Testing with GPS sensor, acceleration and orientation sensors

- Testing of arming logic and error scenarios (low battery, error states, false triggering)

Get a free consultation

We will analyse your current challenges together and show you suitable solutions individually, personally and completely for free.